High-Volume CNC Machining

Production Saw and Machine

High-Volume CNC Machining

Our facility turns more than 400,000 parts each week!

Production Saw and Machine’s high-volume production area is designed with the customer in mind. This department spans 65,000 square feet, runs 24 hours daily, and manufactures 400,000 high-quality parts weekly.

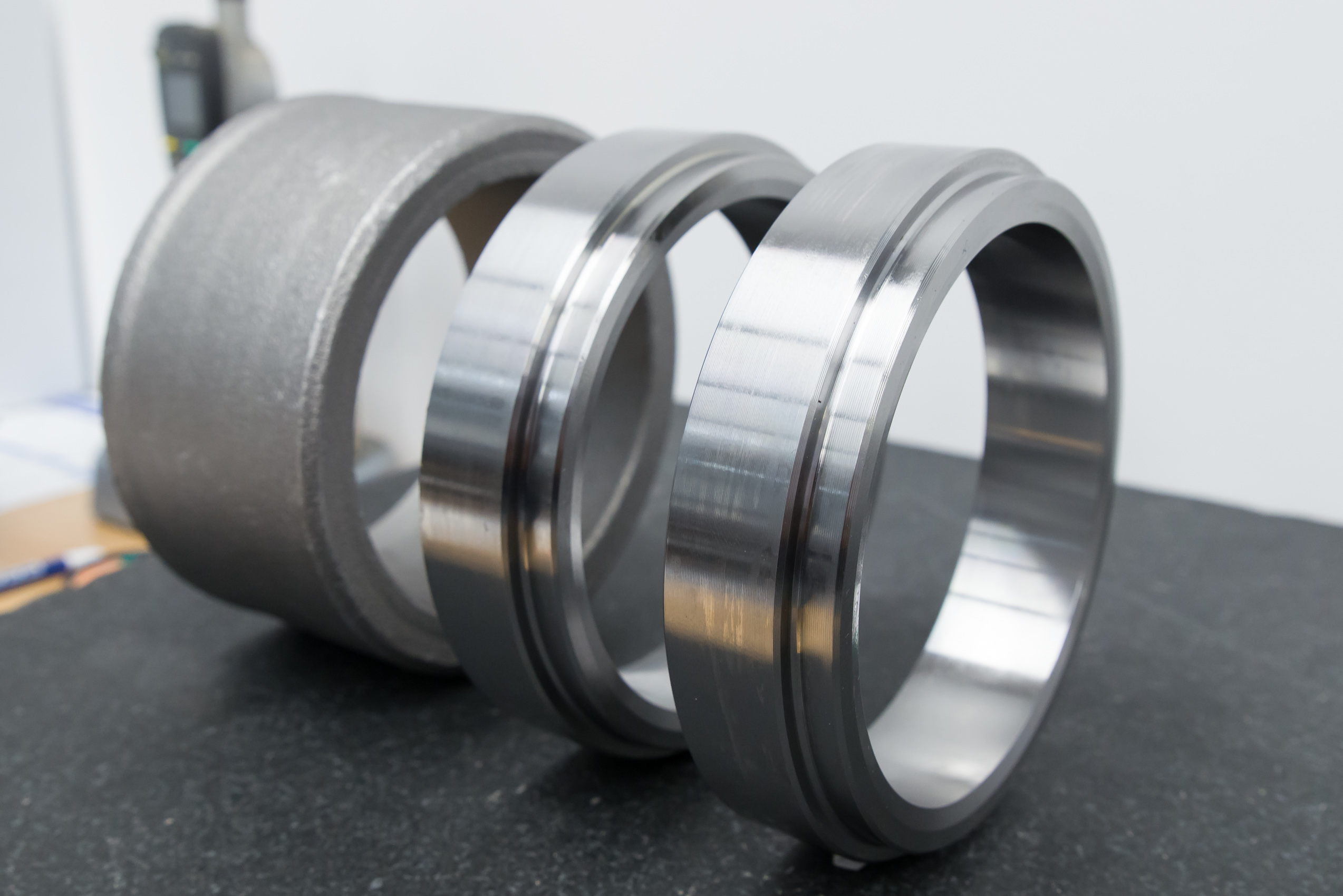

Our ring-making abilities set us apart from other machining companies in the area. Our process varies depending on your needs, such as volume, part complexity, or material yield. Current Ring sizes range from 1″-9″ diameter and volumes from 500 to 40,000 parts per week.

Production Saw and Machine also utilizes Swiss-style manufacturing, which allows us to manufacture a large variety of tight-tolerance parts at an incredible rate.

To meet the demands of our customers, Production Saw and Machine utilizes machine tending automation/robotics and cutting-edge gaging solutions to cut out variables and ensure the highest quality product possible at the desired production rate.

Capabilities & Equipment

- Machining of solids, bar, tubing, forgings or castings

- Gantry load and unload

- Auto-Compensation offset technology

- Cutting-edge robotic machine tending

- Zoller tool pre-setting

- Murata machinery

- FUJI machinery

- Nomura machinery

- CAD/CAM-assisted programming and design

- Cutting-edge engineering department

- Eddy Current part inspection

- Bar-Feed capabilities

- Over 160 turning spindles

An ISO9001 Certified, metric-driven company producing High and Low/Mid-Volume precision machined parts for automotive, industrial, agricultural, and heavy truck Industries.