Production Sawing

Production Sawing

Production sawing is a high-efficiency cutting process used to size steel, aluminum, and other metals quickly and accurately. It reduces waste and shortens cycle time. It also delivers consistent results at scale for automotive, heavy equipment, industrial, and other demanding applications.

Sawing is the core of our operation. It sets the flow of material through your program and supports the quality and repeatability needed for downstream machining and finishing.

Precision Metal Cutting

Production Saw and Machine processes more than 12 million pounds of steel and non-ferrous metals each month. We run rotary cut-off machines, automatic band saws, and CNC cold saws. We cut material from 5/8 inch to 20 inches in diameter and up to 30 feet in length.

Your material stays indoors from the moment it arrives. We track every heat lot through cutting, inspection, and packaging. You receive clean, consistent blanks that support predictable machining and reliable delivery.

Sawing Capabilities

We support small runs and continuous production. We match each job to the right equipment to keep throughput stable and lead times consistent.

Band Saws

- Cut from 1″ to 20″ OD

- Handle bars up to 30 feet long

- Best for large diameters and heavy stock

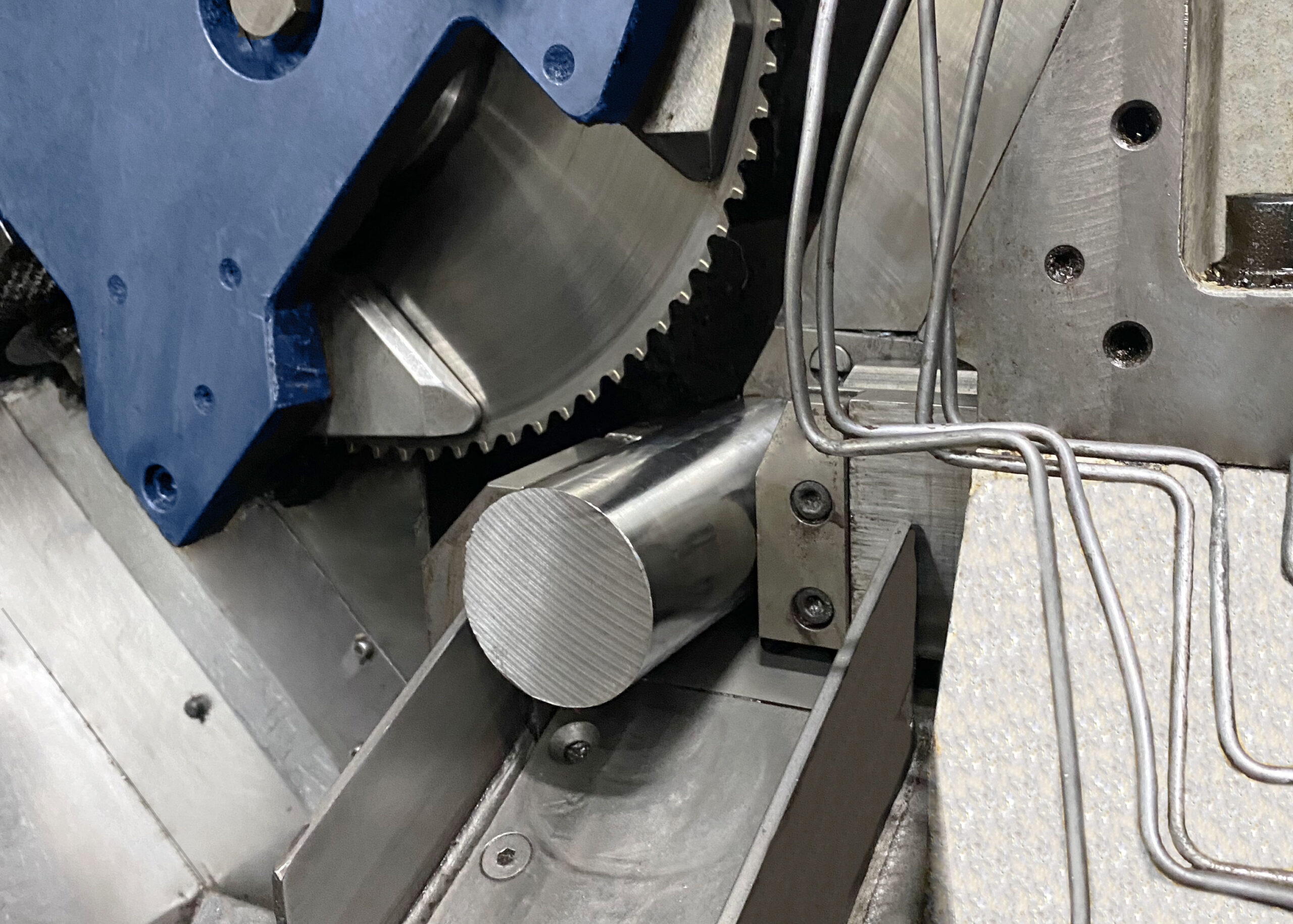

Circular Cold Saws

- Cut solids and tubing from 5/8″ to 4.3″ OD

- High-speed cutting for small and medium diameters

- Multiple saws support parallel production

Rotary Cut-Off

- Cut tubing from 4″ to 7.4″ OD tubing

- Built for high-volume output

- Ideal for short cycle times and bulk tube production

This structure lets you run prototype, mid-volume, and full-scale programs with one supplier.

Material Handling and Traceability

Our 50,000-square-foot sawing center moves material safely and efficiently. Floor-level shipping bays allow fast loading and unloading, including long bars.

Two 7.5-ton overhead cranes unload a 45,000-pound steel truck in minutes. This reduces handling risk and improves delivery flow.

We assign heat and lot numbers at receipt and maintain traceability through every step. You receive ready-to-use parts that support stable machining performance and predictable schedules.

Detailed Capabilities and Equipment

Sawing Capacity

- Total OD Range: 5/8″ to 20″

- Band Saws: 1″ to 20″ OD

- Cold Saws: 5/8″ to 4.3″ OD

- Rotary Saws: 4″ to 7.4″ OD tubing

- Length: up to 30 feet

- Materials: carbon steel, alloy steel, stainless steel, aluminum, and other non-ferrous metals

- Shapes: rounds, squares, flats, tubes, extrusions, and profiles

Equipment

- High-speed circular cold saws

- Band saws up to 20″ OD

- Bardons & Oliver rotary cut-off machines with 7.5-inch OD capacity

- Fully automatic saws from Wagner, Nishijimax, and Behringer

Process and Support

- Automatic length inspections

- Part demagnetization

- Assisted lifts up to 300 pounds

- Gram weight control for forging blanks

Common Part Types

- Camshafts

- Forging blanks

- Axle shafts

- Hitch receivers

- Extruded aluminum shapes

- Rings

- Sun gears

- Pinion blanks

These controls improve part consistency, reduce variation, and support clean machining downstream.

Integrated Value and Finishing Options

Sawing feeds directly into our machining operations and value-added services. Clean, consistent blanks reduce setup time and maintain consistent quality from start to finish.

Through our local supplier network, we provide:

- Gear and hob

- Heat treat

- Grind

- Plate

- Tumble

- Anondize

- Center machining

- Chamfer

- Weld

- Laser engrave

This gives you a single source for cut, machined, and finished parts.

An ISO 9001:2015 Certified, metric-driven company providing production sawing, low- and high-volume precision services for automotive, industrial, agricultural, recreation, and heavy truck industries. See our certification on our Quality page.