Forging Part Services

Precision, Performance, and Reliability in Forged Parts Services

Forged parts demand accuracy, stability, and processes capable of handling challenging materials. Production Saw and Machine supports this with integrated sawing, low-volume machining, and high-volume machining workflows. Our team delivers repeatable quality at scale for automotive, agriculture, heavy equipment, hydraulic, industrial, and defense applications.

Forged part machining is a core strength. It supports stable throughput, reliable quality, and consistent performance across complex shapes and tight tolerances.

Precision CNC Production

We machine forged steels, alloy steels, stainless steels, aluminum, and other non-ferrous materials. Our processes support annual volumes from 250 to 1.9 million parts. We work with forged rings, hubs, housings, carriers, yokes, step bolts, gear blanks, end caps, and other complex geometries.

Sawing integrates directly with machining to provide clean, consistent blanks for downstream operations. This reduces variation and improves machining accuracy on forged material.

Forged Part Showcase

Hover over the images below to learn more about some of our showcased forged parts. This mix reflects our ability to support forged components across multiple industries and volume levels.

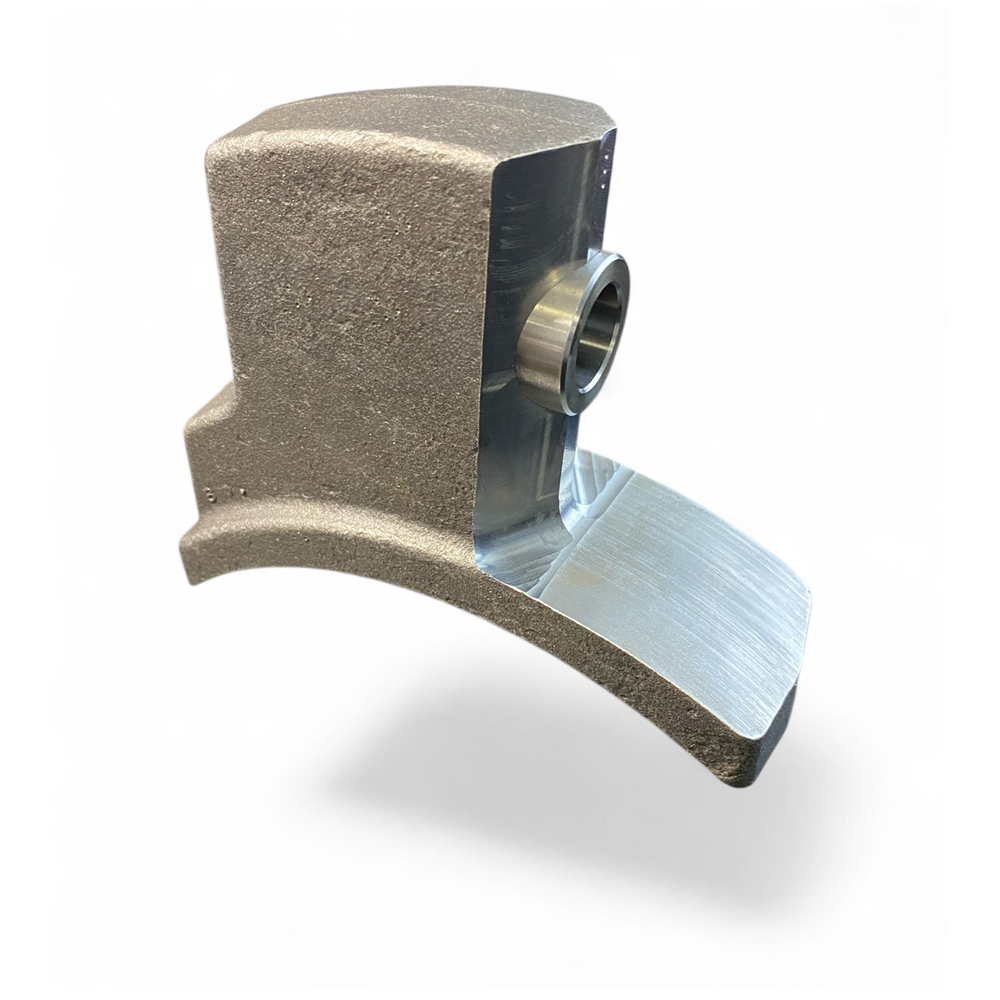

Agriculture Cutting Tool Holder

Material: 8620, Quantity: 120,000 pieces per year, Operations: CNC Machining and Bushing Assembly

Agriculture Step Bolt

Material: 1018, Quantity: 4,000 pieces per year, Operations: CNC Turn

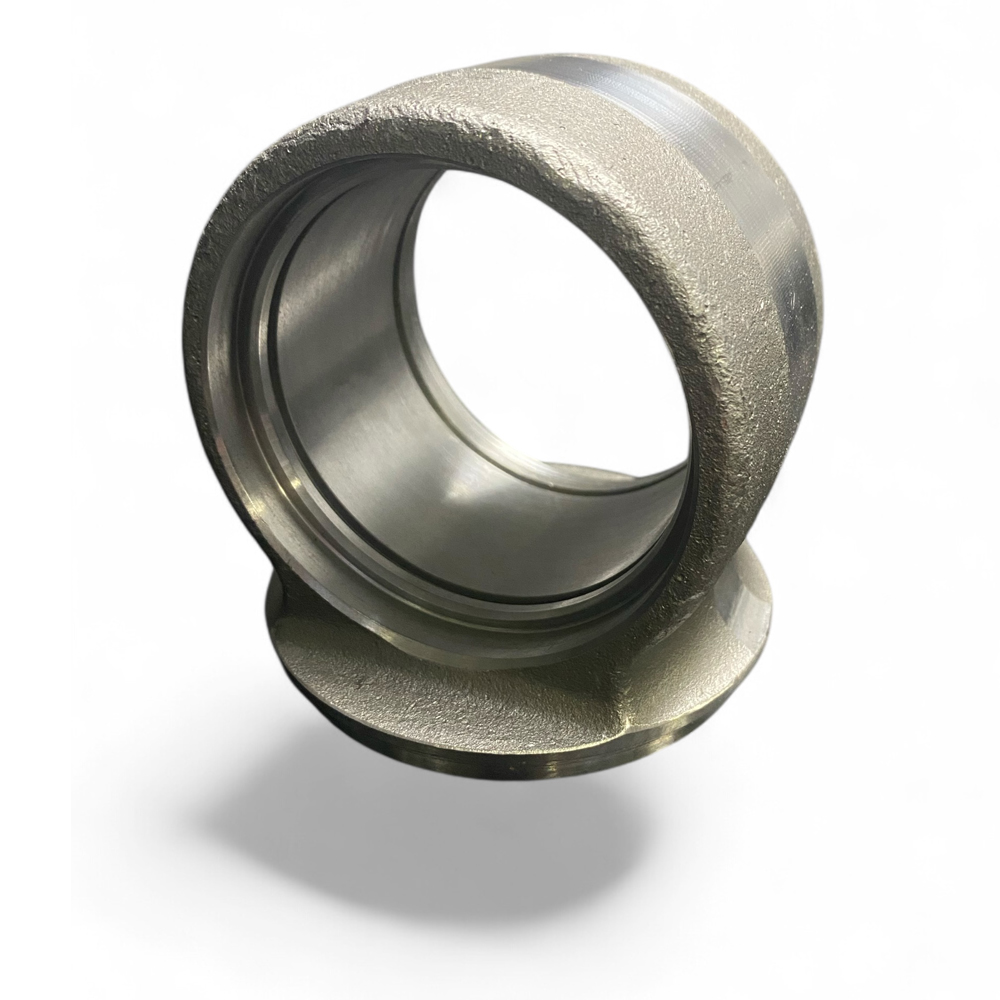

Automotive Annulus Ring Gear

Material: 5135, Quantity: 936,000 pieces per year, Operations: CNC Turn Complete

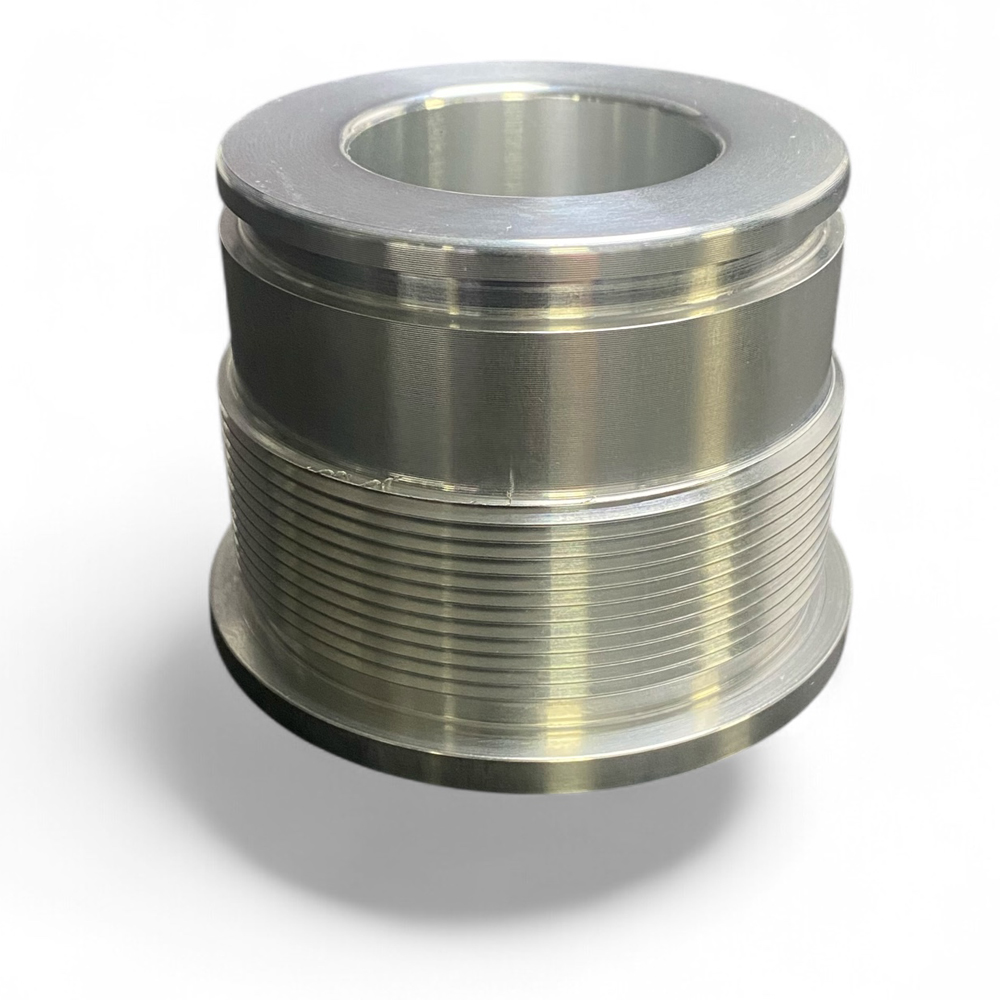

Industrial Hydraulic End Cap

Material: 2024-T6511, Quantity: 50,000 pieces per year, Operations: CNC Turn and Machine Complete

Railroad Directional Control

Material: 4140, Quantity: 2,000 pieces per year, Operations: CNC Machining

Military Lower Post Mount

Material: 4142, Quantity: 4,5000 pieces per year, Operations: CNC Turn and Machining

Why Work with Production Saw and Machine?

Precision & Advanced Techniques

Material Expertise

Scalable Production

Sustainability Focus

Proven Partnership

Production Handling and Traceability

Material moves through controlled steps to maintain accuracy and protect part quality.

- 30,000+ sq. ft. indoor storage for safe, clean material handling

- Two 7.5-ton cranes for efficient unloading and movement

- Bed-level truck bays for fast delivery and pickup

- Heat and lot tracking from arrival through machining and inspection

- Correct packaging and labeling for each shipment

This supports consistent quality for forged components from start to finish.

Detailed Capabilities and Equipment

Production Capacity

- Annual output: 250 to 1.9 million parts

- Support for low-volume, mid-volume, and high-volume forged components

Equipment

- Machining centers and lathes from Mori Seiki, SMEC, Doosan, Samsung, Haas, Brother, DMC, and Fanuc

- Sawing systems from Nishijimax, Bardons & Oliver, and Behringer

- Multi-axis machining capability, including live tooling, 4th-axis, and 3+2 setups

Process and Support

- CAD/CAM programming

- CMM inspection with Brown & Sharpe systems

- In-process gaging and tool monitoring

- Efficient setups for complex forged geometries

These controls support accuracy and stability across forged part programs.

Integrated Value and Finishing Options

Our machining integrates with sawing to deliver clean blanks and accurate machining results. This supports quality and consistency across forging programs.

Through our trusted local network, we provide:

- Gear and hob

- Heat treat

- Grind

- Plate

- Tumble

- Anodize

- Center machining

- Chamfer

- Weld

- Laser engrave

This supports the provision of complete, ready-to-use forged components.

An ISO 9001:2015 Certified, metric-driven company providing production sawing, low- and high-volume precision services for automotive, industrial, agricultural, recreation, and heavy truck industries. See our certification on our Quality page.